AMUT Recycling specializes in the design and construction of plastic recycling plants for bottles and packaging made of PET, HDPE, PP, and PE film. The company holds a unique position in the plastic waste recycling sector, offering state-of-the-art facilities that include advanced front-end sorting systems, high-tech washing lines, and extrusion lines for converting flakes into pellets.

The division’s portfolio also encompasses comprehensive systems for the waste recycling industry, including post-consumer material recovery facilities, post-consumer plastic recovery plants, and equipment for sorting and valorizing waste.

-

Washing plants for PET/HDPE/PP bottles and containers

-

Washing plants for PE film

-

Plastic recovery facilities from post-consumer plastics

-

Material recovery facilities (MRFs) for post-consumer waste

-

Sorting and recovery systems for industrial and municipal solid waste

Headquartered in Germany, Vecoplan AG develops, produces and markets machinery and plants for shredding, conveying and processing primary and secondary raw materials gained in recycling processes. With its technologically sophisticated solutions Vecoplan AG belongs to the leading international companies of the industry for more than 50 years.

The Vecoplan AG-shredding systems produce homogeneous output material in grain sizes suitable for recycling from production waste, mixed plastics, film, intermediate bulk containers and tubular material. They can even process extremely difficult input material such as highly tear-resistant plastic fibres and fabrics, car airbags, FIBCs, textiles, ropes and cords. Innovative rotor cutters and drives ensure high throughput and homogeneous results at low energy costs.

-

Shredding technology: VIZ, VAZ, VEZ V, VEZ

-

Conveying technology: VFB, VKU

-

Storage and dosing technology: VTL, VBE, VDB, VZB,

-

Screw conveyor

BritAS manufactures fully automatic band melt filtration systems for both post-consumer and post-industrial applications.

The ABMF series ensures top efficiency, while piston screen technology is ideal for stable post-industrial waste processing.

-

Melt Filtration

-

Piston Screen Changer

-

Automatic Screen Changer

-

Backflush Screen Changer

-

Recycling system

-

Gas Control

Gneuss supplies innovative filtration, extrusion and measurement technology. Our patented MRS extruder offers new possibilities for the recycling of hygroscopic polymers like PET or polyolefins. Combined with our automatic screen changers the new series of OMNI recycling machines is customized for post-consumer and industrial waste.

AIP, with over 50 years in the filtration industry, is a leader in solutions for plastic extrusion and recycling. We offer advanced technology in engineering, design, manufacturing, technical consulting, and customized services to enhance the performance of your equipment.

-

Laser Filters: Cylindrical: Available in diameters (mm) of 200 and 250. Filtration ratings (microns): 100, 150, 200, 250, 300, 750, 1,000. Round: Available in diameters (mm) of 350, 400, 500, 600, and 700. Filtration ratings (microns): 70, 90, 110, 130, 150, 180, 230, 400.

-

Continuous Band Filters: Available in 230 mm and 308 mm for Britas equipment. High-performance TC, Dutch weave and reverse Dutch weave mesh, offering nominal retention from 600 to 60 microns.

-

Candle Filter: Multiple pleated filtration media combined to ensure product quality, extended filter life, and increased filtration area. Our candle filters are manufactured and customized to meet specific customer performance requirements.

-

Extrusion Filters: Kidney-shaped, welded, framed, packing-type, and sealed filters. Designed and manufactured to meet the most demanding operational requirements in the market.

-

Pyrolytic Oven: Low energy consumption, 2.5X faster than competitors. Equipped with an internal nitrogen generator to create an inert atmosphere that enables polymer decomposition without carbonization. Includes an internal catalyst and post-combustion gas treatment system.

EREMA has its headquarters in Ansfelden in Austria and specialises in the development and manufacturing of plastics recycling systems and components. Founded in 1983, the company is now the world market leader for customised plastics recycling solutions.

-

INTAREMA® TVEplus® DuaFil® Compact

-

VACUREMA®

-

VACUNITE®

-

ReadyMac 500 HD

CALLE CAN CLAPERS 29, NAU 2A

POL. INDUSTRIAL CAN CLAPERS 08181

SENTMENAT, BARCELONA, ESPAÑA

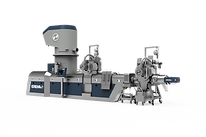

ALTERO specializes in the design and manufacturing of complete extrusion lines for the pelletizing of recycled plastics, both post-consumer and post-industrial.

Founded in 2018, the company brings together over 16 years of technical experience with a focus on compact, robust, and energy-efficient solutions, operating from its facilities near Barcelona. Its lines, installed in more than 15 countries, are capable of processing a wide variety of materials—including agricultural films, stretch films, foams, and rigid flakes—even those with high levels of moisture or contamination, thanks to a modular architecture that adapts to the specific needs of each customer.

ALTERO’s value proposition is grounded in operational efficiency, long-term technical support, and a customer-centric approach.

It operates one of the most advanced testing centers in Southern Europe, enabling real-world process validation and supporting R&D projects. In addition, the company delivers European technology with agile, close, and Spanish-language support, integrating Industry 4.0 standards for remote diagnostics, predictive maintenance, and real-time process optimization.

-

VELOX – High-Performance Pelletizing Lines

-

DUPLO – Cascade Systems

-

OPTIMA HW – Inhouse Pelletizing

of Rigid Post-Industrial Material

-

OPTIMA LW – Inhouse Pelletizing

of Flexible Post-Industrial Material

-

VACUREMA®

-

INLINE – Direct Inline Recycling

-

PYROTECH – Uninterrupted Chemical Recycling Feed Systems

Starlinger recycling technology and Starlinger Viscotec are divisions of Austrian-based Starlinger & Co GmbH, world market leader in the field of machinery and complete lines for woven plastic packaging production. They provide machinery solutions for the recycling and refining of a wide scope of plastics such as PE, PP, PA, PS, BOPP and PET. Starlinger PET recycling systems produce food-safe rPET and are approved for use in food applications by many brand owners as well as various national and international authorities. The worldwide sales and service support network and technical consulting service help customers to achieve optimum results in the manufacturing process.

Starlinger is a participant of the United Nations Global Compact, the world’s largest corporate sustainability initiative, and follows its principles on responsible business practices.

MAS Austria develops advanced machinery for recycling plastics and biopolymers. With a focus on efficiency, sustainability, and process control, MAS enables circular economy solutions through extrusion, filtration, and dry-cleaning systems.

-

Conical co-rotating twin-screw extruder – Designed for efficient recycling and compounding

-

Continuous Disc Filter (CDF) – High-throughput, self-cleaning melt filtration

-

DRD “washing without water” system – Water-free cleaning and drying of plastic waste

-

PET line – Optimized for bottle-to-bottle and tray-to-tray recycling

-

Recompound line – Tailored for recycled content compounding

-

Twin compound line – High-performance masterbatch and filler compounding

Global market leader with over 30-years of experience, Macdermid Enthone provides tailor-made solutions for the plastic recycling industry. Our portfolio includes cleaners, separation agents and antifoams used in food and general applications in plastic recycling lines all over the world.

-

Surfactant

- Master S2

- Master S4 (Silicone based Separation Additives)

- Master S8

-

Antifoam

- ANS TH (Silicon based antifoam)

- ANS HC

-

Detergents

- ADDITIVE RP 34 (High quality detergent specifically designed for Stirrer Washing Systems)

- ADDITIVE RP 38 (High quality detergent specifically designed for Friction Washing Systems)

- ADDITIVE RP 221 (Low foam detergent suitable for all washing technologies)

FIMIC’s history dates back to 1963 and for the last 25 years it has been recognized as a leading manufacturer and specialized supplier of automatic self-cleaning melt filtration technologies. This Italian Family Company is the only one in the market with a range of seven different models of automatic melt filters, capable to target highly contaminated plastics, especially post-industrial and post-consumer plastics, and a series of screw pump solutions that allow to easily transport post-consumer plastics melted by the extruder to the filter without using gears.

FIMIC keeps improving its filtration technologies in order to meet and satisfy the needs (quality, characteristics) of recyclers, and at the same time facing the challenges of filtering out the ever increasing contaminations in post-consumer and post-industrial plastics.

-

Melt Filters – RAS, ERA, RPS, FCS, GEM, TEN

-

Guillotines

-

Screw Pump – SPA

Bernal Industrial is a USA-based consultative technical sales and service organization. We have been working with clients from TX to Southern CA, Mexico, Colombia, and surrounding areas for over 30 years.

AV. INDUSTRIAL 200, PARQUE INDSUTRIAL TOLUCA 2000

TOLUCA, ESTADO DE MÉXICO, C.P. 50233

Avient Corporation stands as a leader in delivering specialized and sustainable material solutions, transforming customer challenges into opportunities and developing innovative products for a better future. Our extensive portfolio includes specialized engineering materials, high-performance fibers, advanced composites, and color and additive systems. With our deep expertise in material science, we make a meaningful impact across nearly every end market — from construction and healthcare to energy and defense.

-

Smart heat

-

Hydrocerol

-

Oxyloop

-

Capture

NGR is an Austrian company specializing in the manufacturing of machinery for the mechanical recycling of post-industrial and post-consumer plastics. With more than 28 years of experience in pelletizing, NGR provides optimal solutions to meet the market’s highest quality standards.

VÍA JOSÉ LÓPEZ PORTILLO, BODEGA 2

SAN MATEO CUAUTEPEC 54948, TULTITLAN, EDO DE MÉXICO

United Rubber Corp has been an industry leader in Mexico for more than 25 years, distributing world-class raw materials, additives, and equipment for the plastics and rubber sector. At United Rubber Corp, we believe in “the power of the local in a global world.”

ISO 9000-2015 certified, we deliver solutions that maximise quality, efficiency, and competitiveness.

-

Advanced lubricants for plastic processing

-

High-performance coupling agents

-

Flow modifiers for PP and PP/PE blends

-

Odor and VOC control: effective masking and neutralizing solutions

-

Impact modifiers for increased toughness

-

Dispersing agents for high-filler compounds

-

Innovative WPC technology: lubricants, coupling agents, and CAPSTOCK

-

SOFT-CAPSTOCK: Innovation in flexible coating systems (New Product)

-

Automatic chemical weighing systems: COLOR SERVICE (BATCH-TRAIN)

-

Machinery and specialized services for the recycling sector

AV. INDUSTRIAL 200, PARQUE INDSUTRIAL TOLUCA 2000

TOLUCA, ESTADO DE MÉXICO, C.P. 50233

It’s not waste, it’s a resource: Whether PET, PE, PP or PS: At Krones Recycling you will find high-quality recycling solutions – from individual modules to complete factories. The goal: to make plastics recycling even more efficient, more sustainable and therefore even more profitable.

-

Turnkey plants for plastics recycling (PET, LDPE, HDPE, PP and PS)

-

Modules for grinding, washing, sorting and decontamination

-

Washing Module MetaPure Compact

-

Washing Module MetaPure Performance

-

Decontamination Module XtraPure

-

Single Machines for plastic recycling plants (e.g. our intensive washer with patented hot-washing)

-

Krones Recycling Technology Center

-

Waste water treatment

Alandro Plastic Resources is a company dedicated to the comprehensive management of special waste through the collection, sorting, grinding, pelletizing, blending, shredding, decontamination, and quality testing of materials. Using state-of-the-art equipment, we ensure their reprocessing and give them a second useful life.

-

Engineering resins (e.g., PC, PE, PC/ABS, ABS, Nylon, PBT, PP)

Aduro Clean Technologies is a Canadian chemical technology company headquartered in London, Ontario, and founded in 2011. The company has developed an innovative technology platform focused on driving environmental sustainability through advanced chemical recycling solutions.

At the heart of its operations is its proprietary Hydrochemolytic Technology (HCT), a transformative solution that converts hard-to-recycle plastic waste and heavy crude oils into high-value resources, such as feedstocks for fuels and chemicals.

Nordson BKG® empowers the plastics industry with cutting-edge solutions for polymer processing and recycling. The BKG® HiCon™ K-SWE-HD/RS continuous backflush melt filter tackles even highly contaminated recyclates, enabling up to 100% recycled polymer use without production stops. Its robust double-piston design, automated backflush, and melt-pressure-controlled venting deliver uninterrupted melt flow and superior film quality for extrusion and blown film applications.

For large-scale polyolefin recycling, the BKG® CO-Line ensures continuous operation with intelligent pump control and automated venting, allowing screen changes on the fly while maintaining throughput. Paired with BKG® underwater pelletizing systems, processors achieve uniform, high-quality pellets from virgin or recycled materials. Together, these innovations boost efficiency, reduce waste, and advance the circular economy—making Nordson BKG® the trusted partner for sustainable polymer processing worldwide.

-

BKG® HiCon™ K-SWE-HD/RS. (Automated Backflush Filtration System, Recycling)

-

DO-Line, CO-Line, CFO-Line (Line Concepts for High-Throughput Polyolefin Recycling – Joint development with FIMIC Srl.)

-

BKG® Underwater Pelletizing Systems

APR is a US-based international non-profit and the only North American organization focused exclusively on improving recycling for plastics. APR’s tools & resources help companies design packaging that can be recycled, support innovations that overcome existing recycling challenges, and encourage stable and reliable markets for post-consumer recycled content.

Headquartered in Switzerland, BUSS ChemTech AG’s patented pyrolysis-based recycling technology features truly continuous operation, minimal residence time and highly efficient and controlled transfer of heat to the molten polymer to maximize oil yield and quality.

-

PyroFilm Reactor Systems for Mixed Plastic Waste Recycling

Kreyenborg is a family-owned mechanical engineering company in Germany (since 1953) that specializes in plant engineering for the plastics and food industries. Its innovative infrared technology has become an energy-efficient and fast way to thermally treat plastics.

-

Machinery, plant and equipment for processing (incl. preprocessing and recycling)

-

Recycling plants for sorted waste, flat films and sheets

-

Compounding lines

-

Mixers, continuous type, for solids

-

Driers for bulk materials

-

Volumetric dosing and metering equipment

Leistritz Extrusion Technology is one of the global leaders in twin-screw extrusion systems, delivering high-performance solutions for masterbatch, compounding, recycling, pharmaceutical and food applications, backed by German engineering and worldwide technical service.

-

In-house extrusion facilities: Scalable trial capabilities with throughput up to 3,000 kg/h for a wide range of polymers, recycling and compounding applications at our new Innovation Center.

-

Cascade extrusion systems: Single-step recycling and compounding solutions using single-screw/twin-screw or twin-screw/twin-screw configurations, delivering improved homogenization, enhanced devolatilization performance, reduced VOCs and minimized gel formation.

-

Inline MFR control: Real-time, inline process monitoring and control using the Leistritz rheometer, ensuring consistent recycled material quality without yield losses or quality degradation.

-

Recycled flooring extrusion: High-performance multilayer panel extrusion using rPP instead of PVC, enabling 100% recyclable flooring solutions.

-

Food and protein extrusion: Twin-screw extrusion technology for meat analogues and flavor encapsulation, featuring hygienic design.

Cutmetall, with three manufacturing plants in Germany, produces industrial knives and wear parts for the recycling industry. The company delivers customized solutions that optimize performance in shredders and granulators, supported by specialized engineering, a comprehensive product portfolio, and technical support for the LATAM market.

-

Shredder knives

-

Granulator knives

-

Cutting Crowns

-

Pelletizer knifes

-

Screens for Shredder & Granulator

-

Laser filter screens

-

Knife holder

-

Sealing Rings

-

Climbing Bars

-

Fastering Materials / Hardware

%201.png)

.png)

.png)

.jpg)

.jpg)

.jpg)

.png)

.jpeg)